- Home

- Solid-Core Post Insulators

Solid-Core Post Insulators

At Winwin Speciality Insulators (WSI), we take immense pride in being one of the foremost manufacturers of Solidcore post insulators in India. With a commitment to excellence, innovation, and the highest industry standards, we have established ourselves as a trusted name in the electrical insulation industry.

Our Diverse Applications

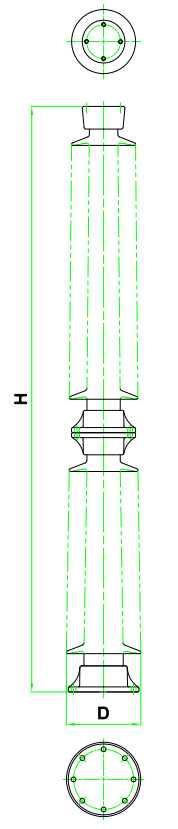

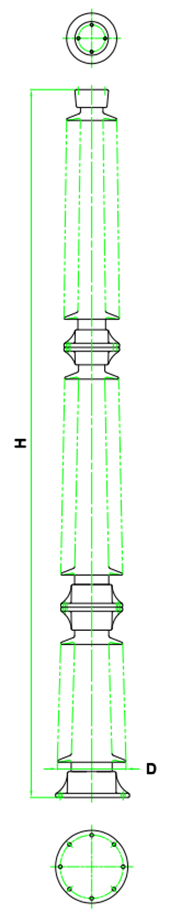

Height and Diameter Flexibility for Your Unique Needs

Height Versatility

Diameter Strength

Creepage Distance Expertise

Innovating for Tomorrow

Stringent Quality Assurance

WSI Product Range

-

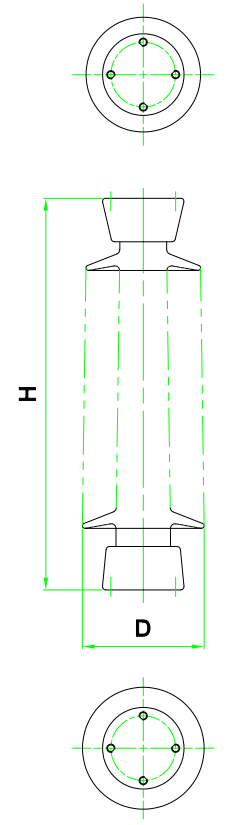

SOLIDCORE C4-325 TO C10-325

-

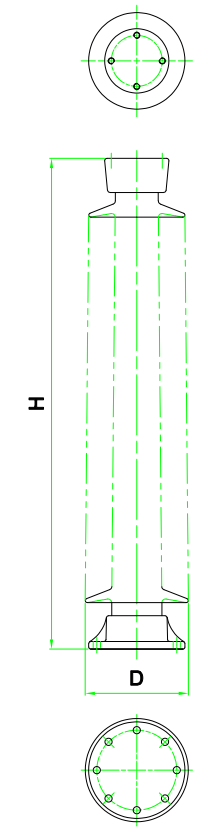

SOLIDCORE C6-450 TO C6-550

-

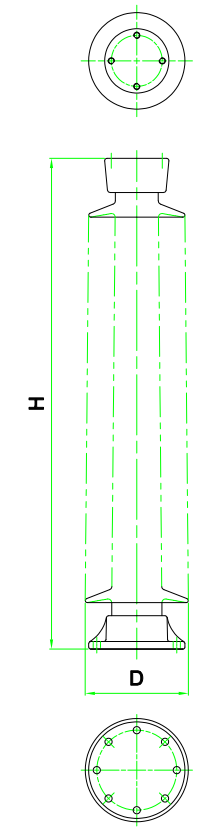

SOLIDCORE C4-650 TO C4-750

| IEC Designation | Units | C4-325 | C6-325 | C8-325 | C10-325 |

|---|---|---|---|---|---|

| Cantilever Strength (upright) | kN | 4 | 6 | 8 | 10 |

| Rated Voltage | kV | 66 | 66 | 66 | 66 |

| Total Height | mm | 770 | 770 | 770 | 770 |

| Max. Diameter of Insulating Part | mm | 191 | 201 | 222 | 245 |

| Top Metal Part Diameter | mm | 160 | 160 | 160 | 160 |

| Bottom Metal Part Diameter | mm | 160 | 160 | 160 | 175 |

| Top Pitch Circle Dia. | mm | 127 | 127 | 127 | 127 |

| Number of Holes and Hole dia. | mm | 4 x M16 | 4-M16 | 4 x M16 | 4 x M16 |

| Bottom Pitch Circle Dia. | mm | 127 | 127 | 127 | 127 |

| Number of Holes and Hole dia. | mm | 4 x M16 | 4-M16 | 4 x M16 | 4 x M16 |

| Total Creepage Distance | mm | 1850 | 1850 | 1850 | 1850 |

| Dry Power Frequency Withstand Voltage | kV | 170 | 170 | 170 | 170 |

| Wet Power Frequency Withstand Voltage | kV | 140 | 140 | 140 | 140 |

| Impulse Withstand Voltage Positive | kVp | 325 | 325 | 325 | 325 |

| Impulse Withstand Voltage Negative | kVp | 325 | 325 | 325 | 325 |

| Dry Power Frequency Flashover Voltage | kV | 200 | 200 | 200 | 200 |

| Wet Power Frequency Flashover Voltage | kV | 170 | 170 | 170 | 170 |

| Impulse Flashover Voltage Positive | kVp | 350 | 350 | 350 | 350 |

| Impulse Flashover Voltage Negative | kVp | 375 | 375 | 375 | 375 |

| RIV Test Voltage | kV | 46 | 46 | 46 | 46 |

| Maximum RIV | ?V | 200 | 200 | 200 | 200 |

| Visible Discharge Voltage | kV | 53 | 53 | 53 | 53 |

| Tensile Strength | kg | 5000 | 6000 | 6000 | 6000 |

| Torsion Strength | kgM | 200 | 250 | 300 | 400 |

| Compression Strength | kg | 10000 | 12000 | 12000 | 12000 |

| Weight (approximate) | kg | 32 | 33 | 39.5 | 41.5 |

| IEC Designation | - | C6-450 | C4-550 | C6-550 |

|---|---|---|---|---|

| Cantilever Strength (upright) | kN | 6 | 4 | 6 |

| Rated Voltage | kV | 66 | 110 | 110 |

| Total Height | mm | 1020 | 1220 | 1220 |

| Max. Diameter of Insulating Part | mm | 187 | 220 | 242 |

| Top Metal Part Diameter | mm | 160 | 160 | 160 |

| Bottom Metal Part Diameter | mm | 160 | 220 | 240 |

| Top Pitch Circle Dia. | mm | 127 | 127 | 127 |

| Number of Holes and Hole dia. | mm | 4 x M16 | 4 x M16 | 4 x M16 |

| Bottom Pitch Circle Dia. | mm | 127 | 178 | 200 |

| Number of Holes and Hole dia. | mm | 4 x M16 | 4 x 18 | 4 x 18 |

| Total Creepage Distance | mm | 2000 | 3400 | 3400 |

| Dry Power Frequency Withstand Voltage | kV | 200 | 250 | 250 |

| Wet Power Frequency Withstand Voltage | kV | 185 | 230 | 230 |

| Impulse Withstand Voltage Positive | kVp | 450 | 550 | 550 |

| Impulse Withstand Voltage Negative | kVp | 450 | 550 | 550 |

| Dry Power Frequency Flashover Voltage | kV | 220 | 280 | 280 |

| Wet Power Frequency Flashover Voltage | kV | 200 | 250 | 250 |

| Impulse Flashover Voltage Positive | kVp | 475 | 570 | 570 |

| Impulse Flashover Voltage Negative | kVp | 500 | 590 | 590 |

| RIV Test Voltage | kV | 53 | 78 | 78 |

| Maximum RIV | ?V | 200 | 200 | 200 |

| Visible Discharge Voltage | kV | 53 | 88 | 88 |

| Tensile Strength | kg | 6000 | 6000 | 7000 |

| Torsion Strength | kgM | 350 | 300 | 400 |

| Compression Strength | kg | 12000 | 12000 | 14000 |

| Weight (approximate) | kg | 47 | 56.5 | 67 |

| IEC Designation | Units | C4-650 | C6-650 | C4-750 |

|---|---|---|---|---|

| Cantilever Strength (upright) | kN | 4 | 6 | 4 |

| Rated Voltage | kV | 132 | 132 | 154 |

| Total Height | mm | 1500 | 1500 | 1700 |

| Max. Diameter of Insulating Part | mm | 223 | 234 | 229 |

| Top Metal Part Diameter | mm | 160 | 160 | 160 |

| Bottom Metal Part Diameter | mm | 240 | 240 | 240 |

| Top Pitch Circle Dia. | mm | 127 | 127 | 127 |

| Number of Holes and Hole dia. | mm | 4 x M16 | 4 x M16 | 4 x M16 |

| Bottom Pitch Circle Dia. | mm | 200 | 200 | 200 |

| Number of Holes and Hole dia. | mm | 4 x 18 | 4 x 18 | 4 x 18 |

| Total Creepage Distance | mm | 3625 | 3625 | 4500 |

| Dry Power Frequency Withstand Voltage | kV | 340 | 340 | 390 |

| Wet Power Frequency Withstand Voltage | kV | 275 | 275 | 325 |

| Impulse Withstand Voltage Positive | kVp | 650 | 650 | 750 |

| Impulse Withstand Voltage Negative | kVp | 650 | 650 | 750 |

| Dry Power Frequency Flashover Voltage | kV | 360 | 360 | 410 |

| Wet Power Frequency Flashover Voltage | kV | 340 | 340 | 375 |

| Impulse Flashover Voltage Positive | kVp | 700 | 700 | 800 |

| Impulse Flashover Voltage Negative | kVp | 725 | 725 | 825 |

| RIV Test Voltage | kV | 92 | 92 | 108 |

| Maximum RIV | ?V | 200 | 200 | 500 |

| Visible Discharge Voltage | kV | 92 | 92 | 108 |

| Tensile Strength | kg | 6000 | 7000 | 6000 |

| Torsion Strength | kgM | 300 | 300 | 300 |

| Compression Strength | kg | 12000 | 14000 | 12000 |

| Weight (approximate) | kg | 64.5 | 73 | 75.5 |

-

SOLIDCORE C6-750 TO C12.5-750

-

SOLIDCORE C6-750 TO C12.5-750

-

SOLIDCORE – C8-1550

| IEC Designation | Units | C6-750 | C8-750 | C12.5-750 |

|---|---|---|---|---|

| Cantilever Strength (upright) | kN | 6 | 8 | 12.5 |

| Rated Voltage | kV | 154 | 154 | 154 |

| Total Height | mm | 1700 | 1700 | 1700 |

| Max. Diameter of Insulating Part | mm | 246 | 247 | 262 |

| Top Metal Part Diameter | mm | 160 | 160 | 160 |

| Bottom Metal Part Diameter | mm | 265 | 265 | 295 |

| Top Pitch Circle Dia. | mm | 127 | 127 | 127 |

| Number of Holes and Hole dia. | mm | 4 x M16 | 4 x M16 | 4 x M16 |

| Bottom Pitch Circle Dia. | mm | 225 | 225 | 254 |

| Number of Holes and Hole dia. | mm | 4 x 18 | 4 x 18 | 8 x 18 |

| Total Creepage Distance | mm | 4500 | 4500 | 4050 |

| Dry Power Frequency Withstand Voltage | kV | 390 | 390 | 390 |

| Wet Power Frequency Withstand Voltage | kV | 325 | 325 | 325 |

| Impulse Withstand Voltage Positive | kVp | 750 | 750 | 750 |

| Impulse Withstand Voltage Negative | kVp | 750 | 750 | 750 |

| Dry Power Frequency Flashover Voltage | kV | 410 | 410 | 410 |

| Wet Power Frequency Flashover Voltage | kV | 375 | 375 | 375 |

| Impulse Flashover Voltage Positive | kVp | 800 | 800 | 800 |

| Impulse Flashover Voltage Negative | kVp | 825 | 825 | 825 |

| RIV Test Voltage | kV | 108 | 108 | 108 |

| Maximum RIV | µV | 500 | 500 | 500 |

| Visible Discharge Voltage | kV | 108 | 108 | 108 |

| Tensile Strength | kg | 7000 | 8000 | 10000 |

| Torsion Strength | kgM | 300 | 400 | 600 |

| Compression Strength | kg | 14000 | 16000 | 20000 |

| Weight (approximate) | kg | 95.5 | 101.5 | 118.5 |

| IEC Designation | - | C4-1050 | C6-1050 | C8-1050 | C8-1175 |

|---|---|---|---|---|---|

| Cantilever Strength (upright) | kN | 4 | 6 | 8 | 8 |

| Rated Voltage | kV | 220 | 220 | 220 | 220 |

| Total Height | mm | 2300 | 2300 | 2300 | 2650 |

| Max. Diameter of Insulating Part | mm | 244 | 261 | 272 | 285 |

| Top Metal Part Diameter | mm | 160 | 160 | 160 | 160 |

| Bottom Metal Part Diameter | mm | 240 | 265 | 295 | 295 |

| Top Pitch Circle Dia. | mm | 127 | 127 | 127 | 127 |

| Number of Holes and Hole dia. | mm | 4 x M16 | 4 x M16 | 4 x M16 | 4 x M16 |

| Bottom Pitch Circle Dia. | mm | 200 | 225 | 254 | 254 |

| Number of Holes and Hole dia. | mm | 4 x 18 | 4 x 18 | 8 x 18 | 8 x 18 |

| Total Creepage Distance | mm | 6125 | 6125 | 6125 | 7600 |

| Dry Power Frequency Withstand Voltage | kV | 490 | 490 | 490 | 560 |

| Wet Power Frequency Withstand Voltage | kV | 460 | 460 | 460 | 460 |

| Impulse Withstand Voltage Positive | kVp | 1050 | 1050 | 1050 | 1175 |

| Impulse Withstand Voltage Negative | kVp | 1050 | 1050 | 1050 | 1175 |

| Dry Power Frequency Flashover Voltage | kV | 510 | 510 | 510 | 590 |

| Wet Power Frequency Flashover Voltage | kV | 490 | 490 | 490 | 560 |

| Impulse Flashover Voltage Positive | kVp | 1100 | 1100 | 1100 | 1250 |

| Impulse Flashover Voltage Negative | kVp | 1150 | 1150 | 1150 | 1300 |

| Wet Switching Surge Withstand Voltage | kV | 750 | 750 | 750 | 850 |

| RIV Test Voltage | kV | 156 | 156 | 156 | 156 |

| Maximum RIV | ?V | 500 | 500 | 500 | 500 |

| Visible Discharge Voltage | kV | 156 | 156 | 156 | 156 |

| Tensile Strength | kg | 6000 | 7000 | 8000 | 8000 |

| Torsion Strength | kgM | 300 | 300 | 400 | 400 |

| Compression Strength | kg | 12000 | 14000 | 16000 | 16000 |

| Weight (approximate) | kg | 123 | 144 | 168 | 196.5 |

One or more columns doesn't have a header. Please enter headers for all columns in order to proceed.

KEY FEATURES

-

UNMATCHED MATERIAL QUALITY

WSI post insulators are crafted using high-strength alumina porcelain, ensuring the utmost durability and reliability. This choice of material underlines our dedication to delivering products that not only meet but exceed expectations, making them ideal for the most demanding electrical applications.

-

VERSATILE RANGE FOR VARIED APPLICATIONS

WSI extensive product portfolio caters to a wide spectrum of applications, including power plants, substations, and distribution networks for supporting bus bars and conductors, isolator applications, switchgear products, pantograph applications, and capacitor bank support etc., WSI post insulators are engineered to excel in diverse scenarios.

-

MEETING DIVERSE ELECTRICAL INDUSTRY NEEDS

At WSI, we recognize the ever-evolving demands of the electrical industry. To cater to a wide spectrum of requirements, our product range spans from 12 kV to 800 kV, ensuring that our solutions are tailored to meet both standard applications and specialized projects.

-

EXPANDING THE LIMITS

In our pursuit of excellence, we are currently in the developmental stages of cutting-edge 1200 kV Solidcore Post Insulators. This underscores our commitment to innovation and our dedication to providing high-quality, reliable products that push the boundaries of electrical infrastructure capabilities.